Views: 0 Author: Site Editor Publish Time: 2025-12-24 Origin: Site

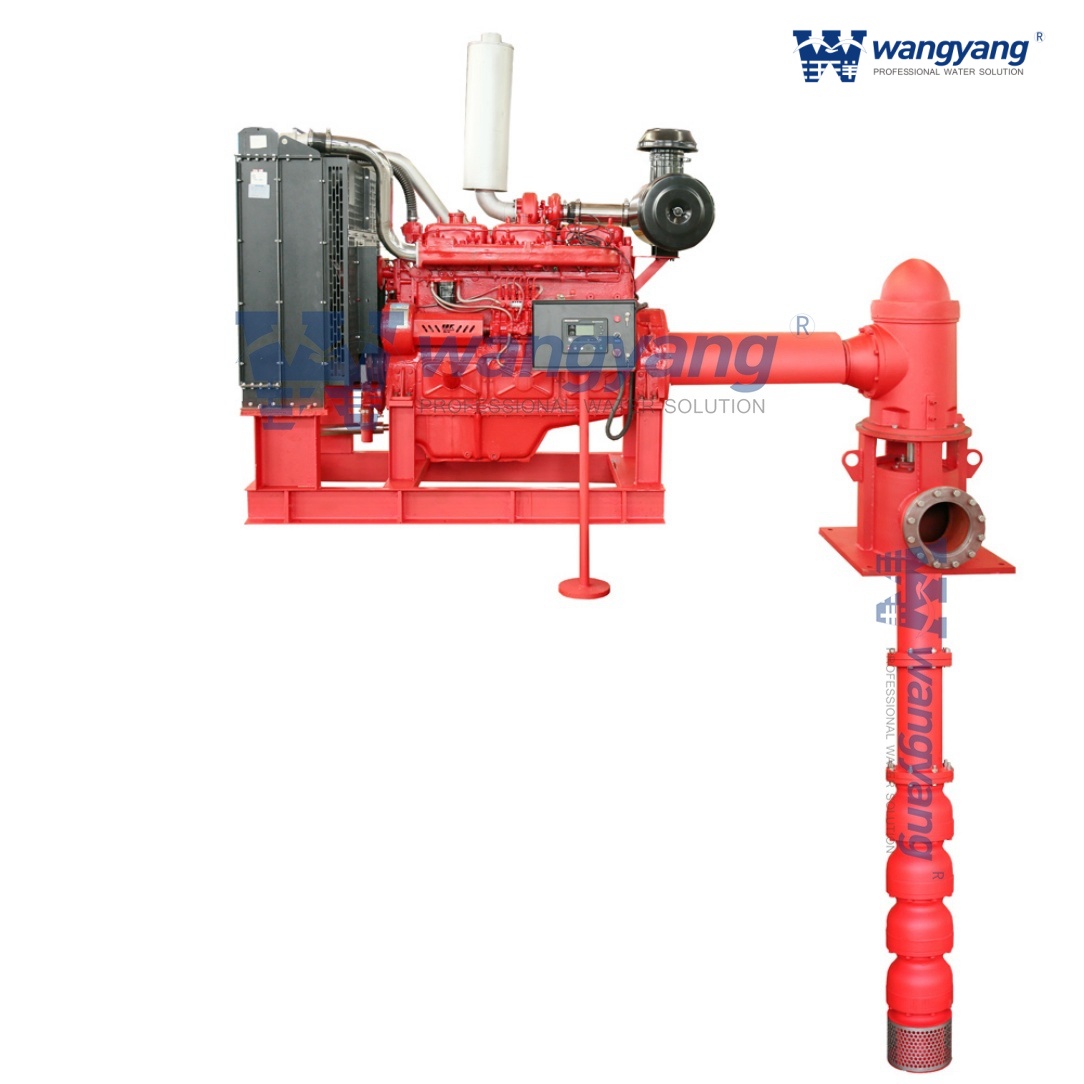

Vertical turbine pumps (VTP) are used to lift fluids from deep wells. Their vertical design allows for efficient fluid movement in deep wells.

In this article, we will explain how these pumps work. We will also discuss their components and common applications. Learn more about our products at Wangyang.

A vertical turbine pump is a type of centrifugal pump used to lift water or other fluids from deep wells or reservoirs. It consists of several key components, including the motor, shaft, impellers, diffuser bowls, and discharge head. These pumps are engineered to be submerged in the fluid being pumped, with the motor positioned above ground level to facilitate easier maintenance and ensure long-term operational efficiency.

Component | Function |

Motor | Drives the pump and is positioned above ground for easier maintenance. |

Shaft | Transfers the mechanical energy from the motor to the impellers. |

Impellers | Rotating blades that increase the velocity of the fluid. |

Diffuser Bowls | Converts kinetic energy into pressure to move the fluid upward. |

Discharge Head | Directs the fluid to the surface pipes or other systems for distribution. |

Vertical turbine pumps are built using high-quality materials such as stainless steel and bronze, ensuring long-term durability even under challenging conditions. The design includes modular components, such as the impeller and diffuser bowl, which can be configured to meet specific performance needs. These pumps can be customized for different flow rates and head heights to suit various applications, whether for municipal water supply or industrial processes.

At the heart of how vertical turbine pumps work is the process of fluid movement. Liquid enters through the suction bell, a bell-shaped component that directs fluid into the pump system. The impellers, which rotate to add energy to the liquid, increase its velocity. As the liquid passes through each stage of impellers and diffuser bowls, its pressure increases, making it easier to move the fluid upwards against gravity.

Impellers play a crucial role in vertical turbine pumps by converting mechanical energy into fluid movement. These rotating blades accelerate the fluid, adding kinetic energy. The diffuser bowls that follow each impeller work to convert this kinetic energy into pressure, helping move the fluid upward with less power. This staged process ensures that vertical turbine pumps can lift large quantities of liquid over significant distances.

After the liquid passes through the final impeller and diffuser bowl, it enters the well bore and reaches the discharge head. The discharge head directs the fluid to surface pipes, allowing it to flow to its next destination. This component ensures that the fluid exits the pump efficiently, maintaining the pressure needed for long-distance transportation.

Vertical turbine pumps are commonly used in various exterior applications, especially where lifting fluids from deep sources is required. These pumps are crucial for water systems, where they ensure a consistent supply of water from underground sources to urban and agricultural areas.

Although vertical turbine pumps are more common in water systems, their versatility can extend to many industrial applications where fluid movement is critical. The combination of high-efficiency performance and durability makes them an ideal choice for high-demand processes such as irrigation and municipal water supply systems.

In certain industries, the versatility of vertical turbine pumps allows for application in manufacturing and even signage, where large amounts of liquid are pumped for operational needs. Their ability to handle high-pressure fluid flow ensures that they can perform well in specialized environments.

Though more commonly used for water and fluid systems, vertical turbine pumps also support processes inside facilities, such as factories or chemical plants, where large-scale fluid movement is necessary. For these purposes, their strength and reliability make them a top choice for facilities needing effective and efficient fluid handling.

As part of industrial systems, vertical turbine pumps also support various operations involving liquid flow. These pumps' high performance ensures that industrial processes, even those related to fluid management inside factories, continue to operate efficiently.

One of the primary advantages of vertical turbine pumps is their durability and minimal maintenance requirements. Since the motor is positioned above ground, maintenance is much more convenient compared to submersible pumps. The design of vertical turbine pumps is straightforward, with fewer moving parts, which reduces the chance of failures and extends the operational life of the pump. This makes them reliable over long periods, reducing downtime and the need for frequent repairs.

Vertical turbine pumps are highly cost-effective in the long term. Their design allows them to efficiently handle high-head applications, making them ideal for large-scale operations like municipal water systems, irrigation projects, and industrial fluid transport. By improving energy efficiency and reducing component wear, these pumps offer significant cost savings. Over time, vertical turbine pumps reduce operational expenses, optimizing the overall cost-effectiveness of fluid-handling systems, and providing long-term value.

Vertical turbine pumps offer aesthetic flexibility for various infrastructure projects. While functionality is a top priority, the design of these pumps can be adapted to meet specific visual needs. By choosing appropriate components such as impellers, diffusers, and discharge heads, engineers can ensure that the pump performs efficiently while fitting within the desired design parameters. This combination of reliability and design flexibility makes vertical turbine pumps a preferred choice in both practical and aesthetic applications.

The core material of vertical turbine pumps plays a critical role in determining their efficiency and longevity. Common materials include stainless steel, which offers excellent corrosion resistance, and cast iron, which is ideal for handling abrasive fluids. When selecting the right material, consider the application’s specific fluid requirements and environmental conditions.

Material | Corrosion Resistance | Durability | Common Use |

Stainless Steel | Excellent, highly resistant | High durability, long life | Ideal for corrosive environments |

Bronze | Good, resistant to saltwater | Durable, resistant to wear | Common in marine or industrial use |

Cast Iron | Moderate, requires coatings | Strong, but susceptible to rust | Suitable for non-corrosive environments |

Carbon Steel | Low, requires protective coatings | High strength but vulnerable to corrosion | Used in low-corrosion applications |

Vertical turbine pumps are available with various coating options, which help protect them from corrosion and wear. PVDF coatings are particularly effective for outdoor applications exposed to UV rays, while other coatings, such as epoxy, may be more suitable for interior applications or less demanding environments.

Vertical turbine pumps can be customized to meet specific flow rate and head requirements. Customizing the impeller size and number of stages in the diffuser bowls ensures that the pump meets the operational needs of different projects, whether it involves large-scale irrigation or water supply systems.

One of the main challenges with vertical turbine pumps is their limited suction head. The suction head determines how deep the pump can effectively draw fluid from, and exceeding this limit can reduce pump efficiency. Proper installation is essential to overcoming this challenge. Ensuring the pump’s components are correctly aligned, selecting the right materials, and installing the system at the optimal depth will help mitigate potential performance issues.

Corrosion is another significant challenge for vertical turbine pumps, especially in environments exposed to aggressive fluids like seawater or chemicals. Prolonged exposure to such environments can cause damage to key components, reducing pump efficiency and lifespan. To prevent corrosion, it is important to select materials with high resistance to corrosion and ensure regular maintenance practices are in place, such as inspecting seals and coating vulnerable parts.

Routine inspections are crucial for the longevity and efficiency of vertical turbine pumps. Regular checks of the motor, shaft, impellers, and diffuser bowls help identify any issues early. Addressing minor wear and tear before they become significant problems ensures that the pump continues to function smoothly and without interruptions, reducing downtime and repair costs.

Preventing common pump failures, such as bearing wear, impeller damage, or misalignment, can significantly extend the pump's life. Regular lubrication, proper alignment of the components, and monitoring operating conditions are essential preventive measures. Keeping a consistent maintenance schedule and promptly addressing any identified issues will help avoid costly repairs and improve the overall performance of the pump.

Vertical turbine pumps are essential for industries requiring efficient fluid movement from deep wells or reservoirs. Their durability, ease of maintenance, and cost-effectiveness make them ideal for applications like municipal water systems and agriculture. By understanding how they work, their key components, and maintenance best practices, you can ensure optimal fluid handling and operational success. Products from Wangyang offer reliable vertical turbine pumps that enhance efficiency and performance.

A: A vertical turbine pump is a type of centrifugal pump designed to lift fluids from deep wells. Its vertical structure allows for efficient fluid movement over long distances.

A: Vertical turbine pumps work by using impellers to accelerate fluid. The liquid is drawn through the suction bell, passed through the impellers, and then moved upward through diffuser bowls.

A: Vertical turbine pumps are ideal for deep wells because their vertical design allows them to effectively handle high-head applications and lift fluids from great depths.

A: Vertical turbine pumps are durable, cost-effective, and require low maintenance. They are suitable for high-efficiency fluid lifting in municipal, agricultural, and industrial applications.