| Availability: | |

|---|---|

| Quantity: | |

Using state-of-the-art techniques from USA in turbine pump design, Wangyang vertical turbine pump covers a wide range of hydraulic conditions to meet virtually every pumping service in the industry with optimum efficiency.

Advantage of Vertical Turbine Pump

Advanced hydraulic model and structure design, Ashland process for core, Epoxy coated in blade passage of impeller, reasonable material selection, excellent product performance, long service life.

• High efficiency, higher 2~8%, than Local J、JD、JC Pump, with flat efficiency curve wide area for high efficiency add 10~20% separation range, significant energy saving effort

• The sand throwing apparatus, a labyrinth structure make the sand cannot enter the bearing

• Impeller and motor shaft is supported copper bearing, shaft runout control within American standard 0.13mm, smooth running, low noise.

• Pump discharge head has beautiful appearance, convenient repair window, is easy to replace packing

• Compared with the same domestic flow pump, the working parts of small diameter about 1 inches, renovation can significantly save the user cost and suitable for pumping well

Cross Sectional Drawing

Specifications of Vertical Turbine Pump

High Capacity and Head: Supports up to 20,000 GPM (4500 m³/h) and heads up to 1600 feet (500m), making it suitable for demanding pumping applications.

Temperature Resilience: Operates at temperatures up to 500°F (260°C), ideal for high-temperature environments.

Versatile Construction: Available in bowl sizes from 6" to 28", with options for casted or fabricated discharge heads and flanged columns.

Durability: Features stainless steel shafting and alloy construction, ensuring long-term reliability in harsh conditions.

Corrosion and Abrasion Resistance: External flush system for critical wear areas, enhancing performance in corrosive or abrasive services.

Efficient Installation and Maintenance: Built-in alignment and simplified piping reduce installation costs and maintenance downtime.

Material of Vertical Turbine Pump

• Bowl: Cast Iron, Ductile Iron, Stainless Steel, Duplex SS, Bronze

• Shaft: Carbon Steel, Stainless Steel, Duplex SS, 17-4PH SS, Model K500

• Impeller: Cast Iron, Ductile Iron, Stainless Steel, Duplex SS, Bronze

• Discharge head: Cast Iron, Ductile Iron, Fabricated Steel, Stainless Steel, Duplex SS

Applications of Vertical Turbine Pump

Utility Circulating Water | Waster Plants | Industrial Process |

Golf Courses/Turf Irrigation | Agricultural Irrigation | Dewatering |

Mining | Cooling Water | Water Parks |

Snowing | Flood Control | Seawater and Raw Water Intake |

| Fire-Fighting | Condenser Circulating Water | Ash Sluice |

The Vertical Turbine Pump with Diesel Engine is ideal for a wide range of applications, including utility circulating water, golf course and turf irrigation, mining, snowing, fire-fighting, wastewater treatment, agricultural irrigation, cooling systems, flood control, condenser circulating water, industrial processes, dewatering, water parks, seawater and raw water intake, and ash sluice systems. Its high capacity, durability, and resistance to corrosion and abrasion make it an optimal solution for demanding environments, ensuring reliable performance in diverse industrial, agricultural, and municipal applications.

1. Pump Bowl Assembly

The bowl assembly is the heart of the vertical turbine pump. The impeller and diffuser type casing are designed to deliver the head and capacity that your system requires in the most efficient way possible. The fact that the vertical turbine pump can be multi-staged allows maximum flexibility both in the initial pump selection and in the event that future system modifications require a change in the pump rating.

A variety of material options allows the selection of a pump best suited for even the most severe services. The many bowl assembly options available ensure that the vertical turbine pump satisfies the users’ needs for safe, efficient, reliable and maintenance-free operation.

2.Flanged Column

Column sections are provided with flanged ends incorporating registered fits for ease of alignment during assembly to ensure concentricity. Our standard bearing retainers are threaded into the column section. Product lubricated lineshaft is recommended for ease of maintenance. Renewable shaft sleeve or hard facing of shaft available for longer life. The enclosed lineshaft is protected by water flushing the enclosing tube bearing on corrosive / abrasive services. Oil lubricated lineshaft available on long settings.

3.Discharge Head

The discharge head functions to change the direction of flow from vertical to horizontal and to couple the pump to the system piping in addition to supporting and aligning the driver. Discharge head accommodates all types of driver configurations. Optional sub-base can be supplied. Wangyang offers three basic types for maximum flexibility.

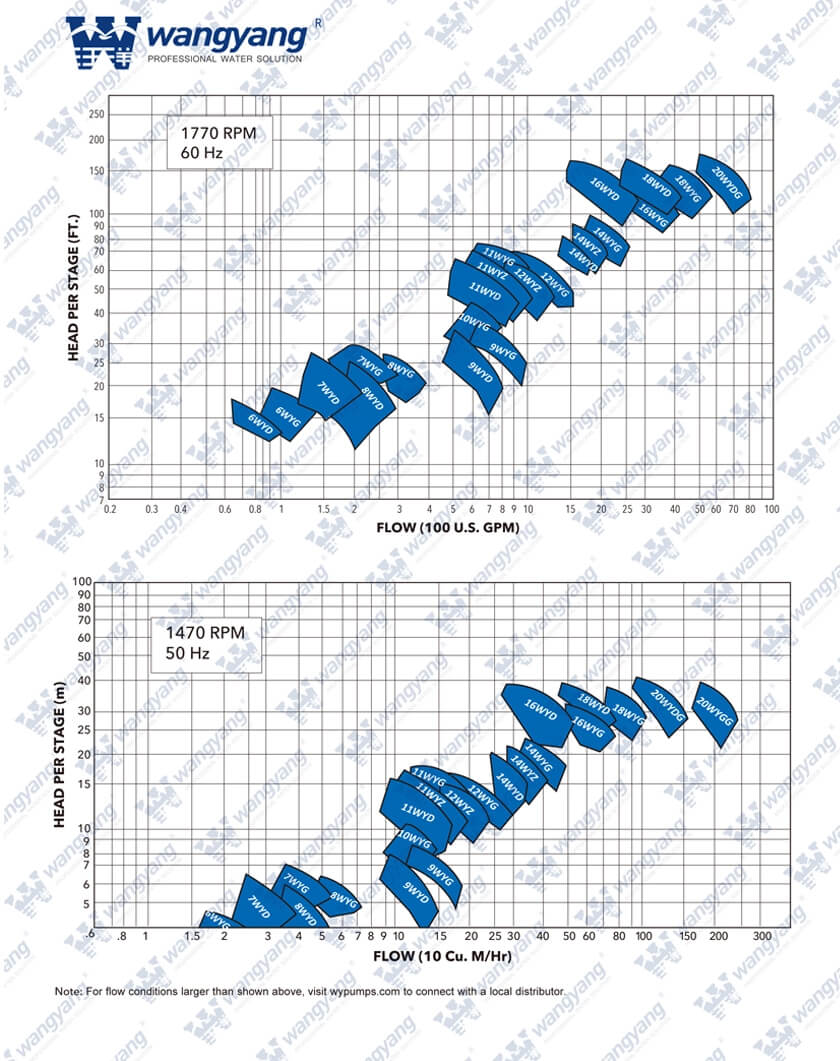

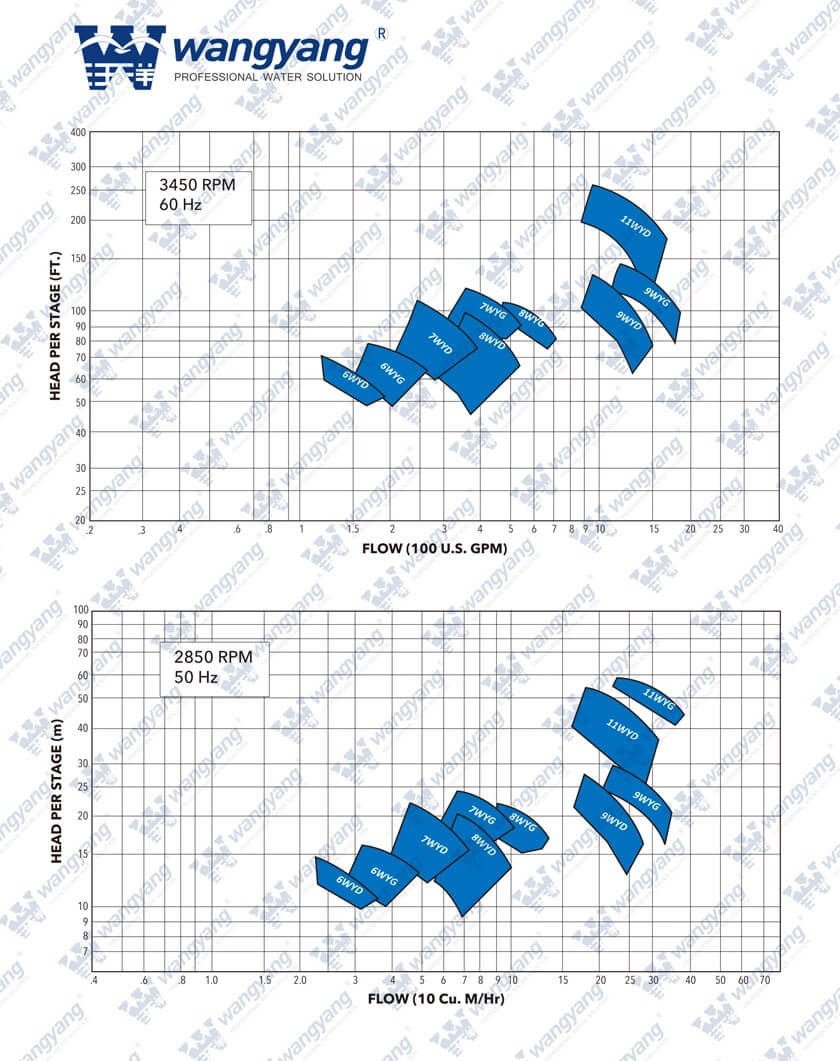

Hydraulic Coverage of Vertical Turbine Pump

|  |

Installation