Wangyang submersible turbine pump consists of discharge adapter, bowl assembly, suction adapter, and submersible motor. The structure is reasonable, easy to install and maintain, and with advanced hydraulic model, they adopting the core produced with the resin sand and the vane runners adopting the core technique that coated with epoxy, high efficiency which is 2-5% higher than that of QJ type submersible deep well pump.

Usage

Submersible turbine pump is used to lift normal temperature clean water without corrosion from well, in discharging from cistern or river, supplying water for high-rise and mine drainage and for water supply and drainage in works and urban area, and lifting underground water, seawater lifting, and etc.

Design Advantage

• Submersible turbine pump is ideal for deep set applications where use of vertical turbine pump is impractical

• Complete unit of submersible turbine pump is installed underground resulting in space-saving, quiet operation, Long life / low maintenance - no lubrication, alignment

Structure Explanation

• Capacity: ≤4500m³/h

• Head: ≤500 m

• Pressures to 2500 psi (76kg/cm2)

• Bowl sizes from 6" to 20"

• Motor Power: 5.5-720W

• Rated Voltage: 380V, 460V, 3kV, 6kV, 10kV

• Well Diameter: 100- 750mm

• Max. Discharge Diameter: 450mm

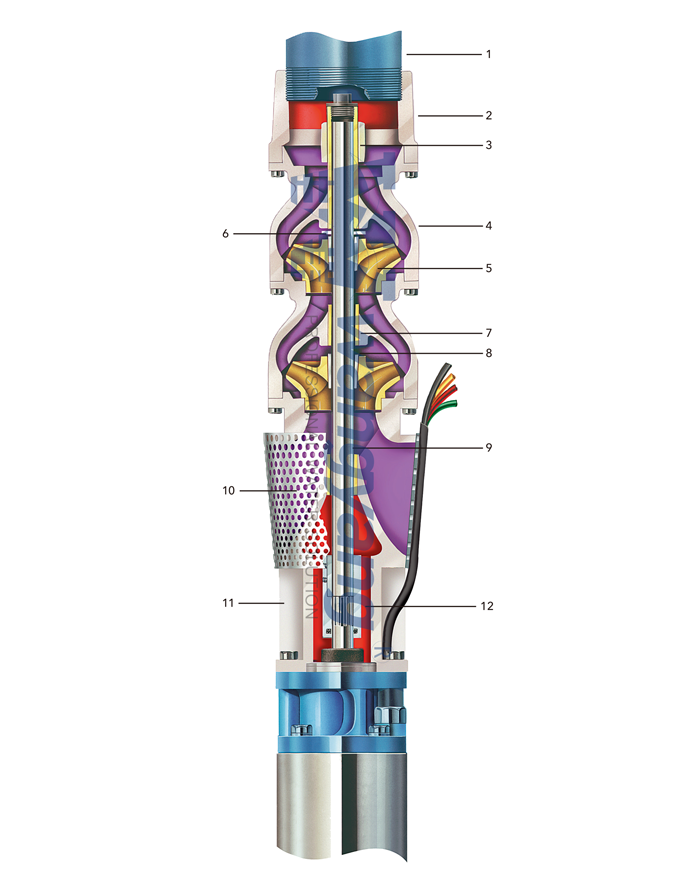

1.Discharge Pipe

Properly sized for optimum water velocities to insure peak hydraulic performance.

2.Discharge Bowl

Several discharge sizes available for NPT or flanged pipe.

3.Discharge Bearing

Extra long top protected bronze bearing insures positive shaft alignment and stabilization for extended life.

4.Intermediate Bowl

Close grained Class 30 cast iron. Water passage glassed formaximum efficiency and abrasion resistance.

5.Impellers

Designed for maximum efficiency with wide range hydraulic coverage. Precision balanced for smooth operation.

6.Upthrust Collar

Designed for extra margin of safety against possible momentary upthrust occurring at startup.

7.Intermediate Bowl Bearings

Reliable long life bronze or rubber bearing.

8.Lock Collets

Accurately machined to insure positive locking of impeller to pump shaft.

9.Pump Shaft

100,000 PSI high tensile stainless steel provides strength and excellent corrosion resistance. Ground and polished for smooth bearing surface.

10.Suction Inlet

Contoured for smooth flow entrance. Protected by an oversized stainless steel strainer to prevent entrance of damaging solids.

11.Suction Adapter

Ductile iron provides for increased strength and positive motor alignment. Open area permits easy access to pump/motor coupling.

12.Pump/Motor Coupling

Large stainless steel coupling accurately machined for perfect alignment, balance and power transmission. Submersible pumps and motors provide an extensive list of options versus other deep well pumping equipment systems. Advanced engineering designs and experience now assure units for long term pumping service. Water well applications provide the perfect opportunity to evaluate features and benefits of submersible equipment.

The system requirements can be met with a choice of pump sizes and selections for the best hydraulic performance. The choice of pump and motor diameters, voltage and specs for varying well conditions provides additional opportunity to match the unit to all the requirements of the system.

The availability of accessory items, cable and controls enables you to rely on Wangyang pumps for units that provide top service.